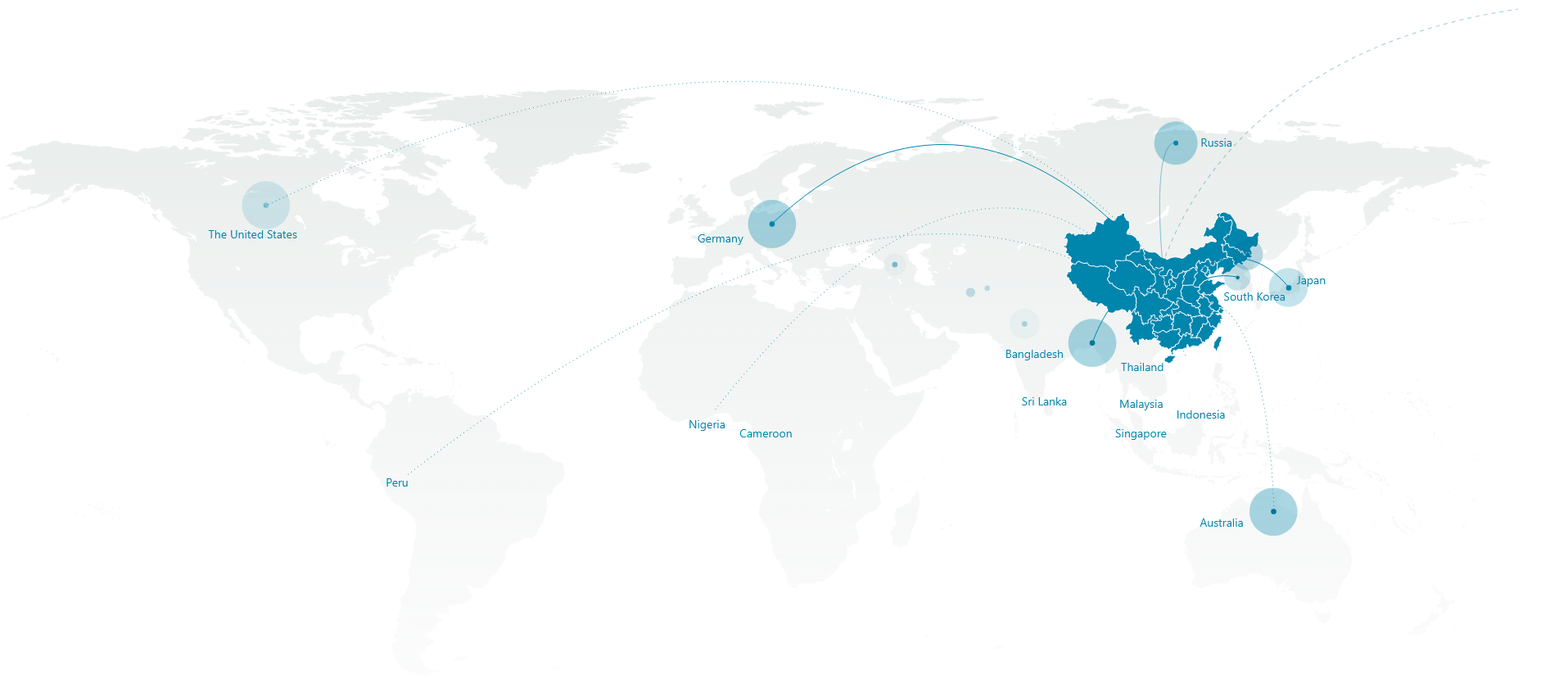

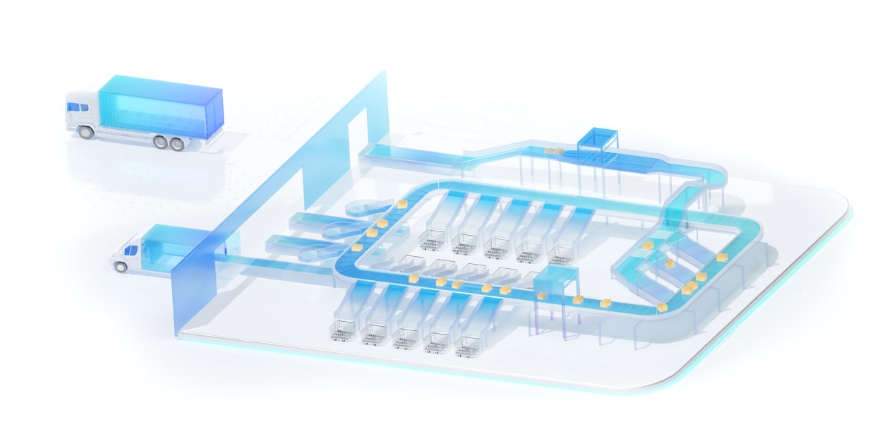

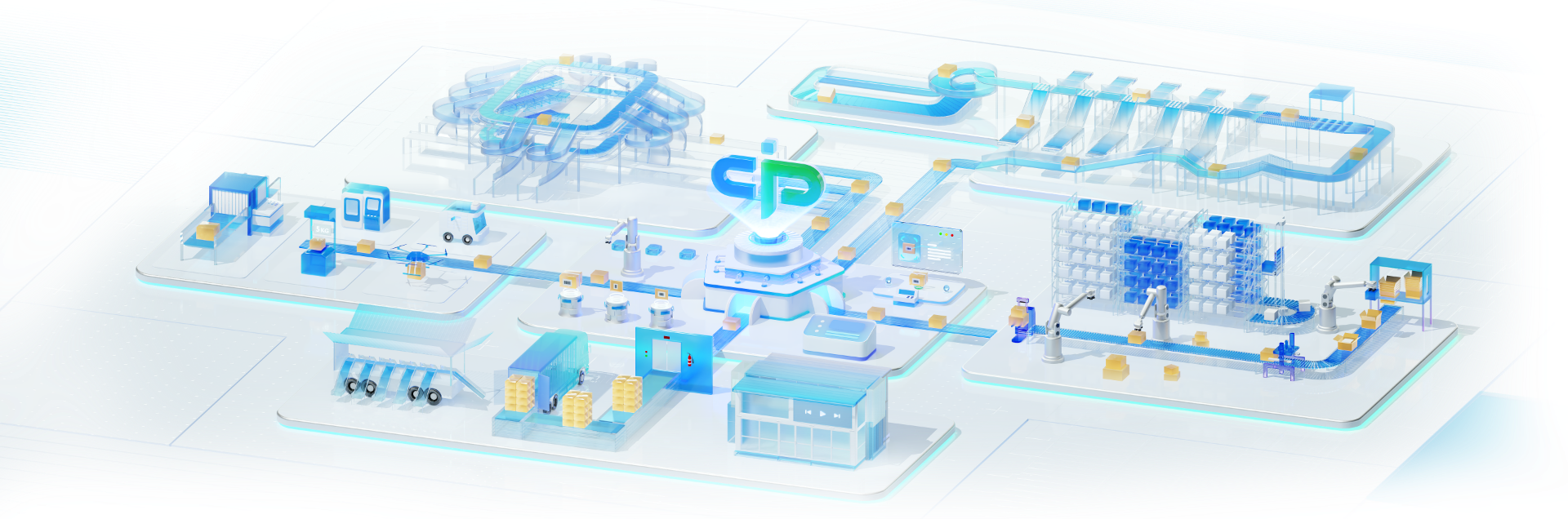

Capable of meeting various specifications of package handling requirements and providing customized express handling solutions for the postal and express delivery industries; We provide research and development, production, integration, and delivery of intelligent logistics equipment, committed to providing customers with one-stop, comprehensive, and customized services to achieve fast, efficient, and reliable operation of express shipments within the processing center.

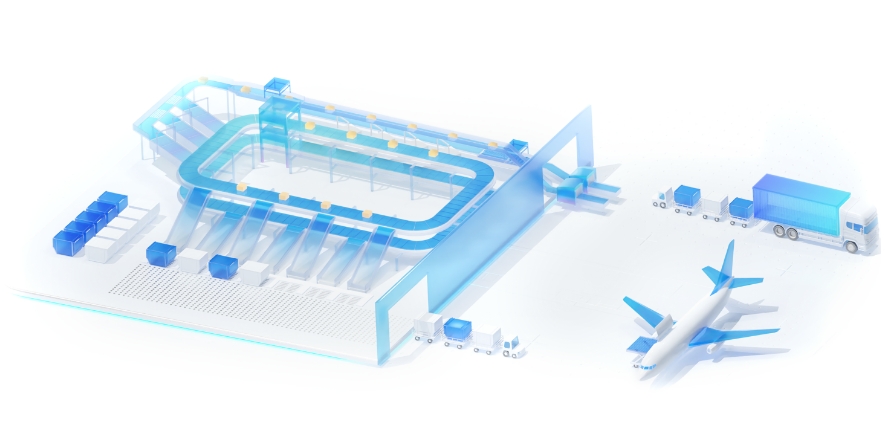

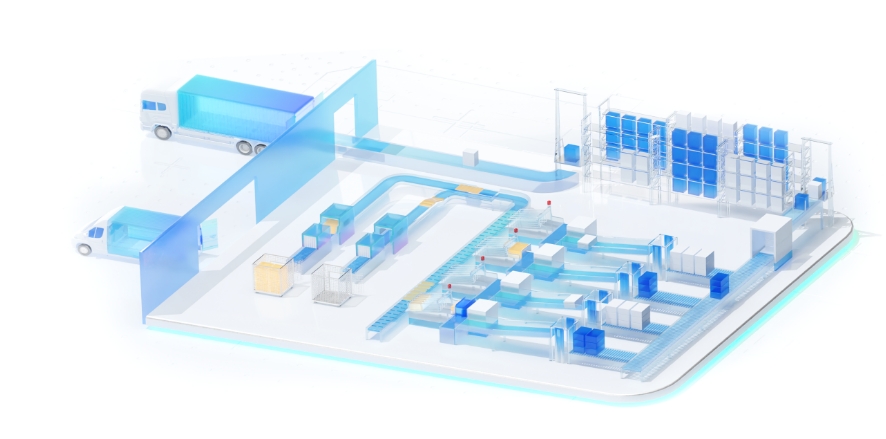

Promote the intelligent process of air cargo logistics, provide intelligent solutions and full process services such as airport express sorting and airport cargo stations, assist in the transformation of air cargo processing to technology intensive, effectively reduce airport logistics facilities and operational costs, improve efficiency, and increase flexibility.

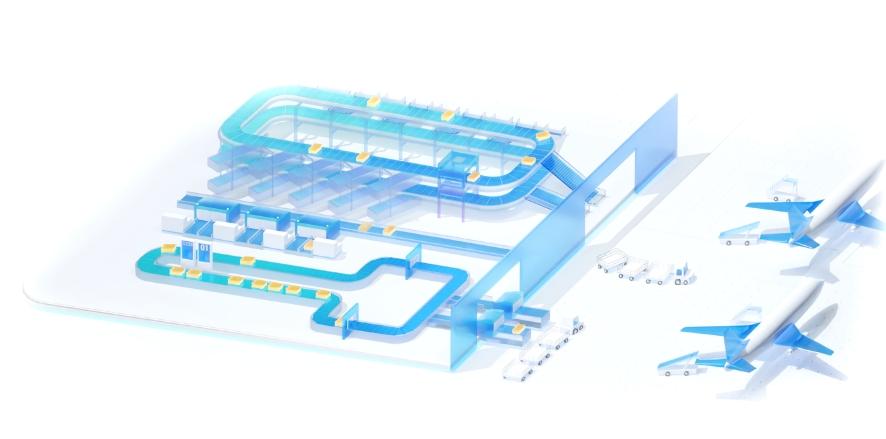

In the airport logistics industry, mature technology, advanced processing processes, and intelligent workflows are combined to efficiently and safely sort and transmit airport passenger luggage, achieving unmanned baggage handling and automatic information exchange, helping to build a smart airport and improve the passenger experience.

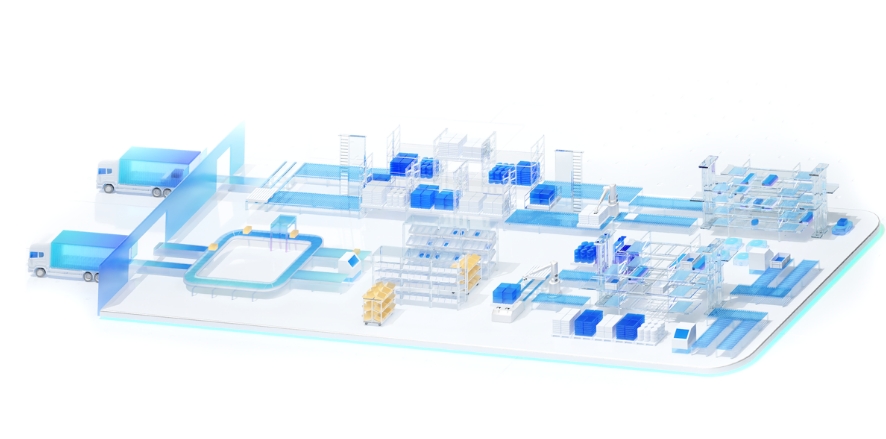

Provide warehousing operation and management solutions for enterprises with warehousing needs in various industries, such as warehousing, relocation, inventory, sorting, transmission, and outbound. Can be customized according to customer specific business needs, effectively improving inbound and outbound efficiency, space utilization, and warehouse management level, supporting the processing of various types of goods in various industries.

We have been committed to the research and development of automated processing in the tobacco logistics industry for a long time, providing automated and informationized tobacco picking and distribution systems for large and medium-sized distribution centers in China. We aim to build an efficient, fast, orderly, accurate, and visible tobacco logistics system, and can add corresponding modules according to business needs to meet different efficiencies.

Automatic loading and unloading truck is a van logistics transport vehicle equipped with automatic loading and unloading device. It is a new special purpose vehicle product created with the rapid development of e-commerce logistics industry.

The automatic loading and unloading device is installed on the floor of the automatic loading and unloading vehicle. The hydraulic motor is the driving force and the high strength circulable chain plate is the transmission carrier. The two-way transmission and automatic loading and unloading of goods are realized under the driving of the front and rear driving devices, which effectively solves the pain points of the vehicle in the loading and unloading process.

China Post Technology independently develops a robotic arm recognition control algorithm, which automatically grabs items in the processing center through autonomous visual recognition technology, effectively replacing manual operations.

Series/parallel connection

Equipment application telescopic telescopic conveying technology. On the basis of the conventional belt conveyor, a multi-stage telescopic structure is added to facilitate free combination adjustment in length and direction. There are two-section conve

The conveyor has cantilever type hydraulic lifting function. It can be operated independently or online.Can realize expansion and cargo transportation synchronization, the loading and unloading and internal transportation system is effectively connected.

It is a brand new carrier of offline interactive marketing. By using automatic control system, integrated system information technology, multi-function varaculture display car technology, carriage and special equipment integration technology, the road&

Has been widely used in home, electrical appliances, automobile, industry, energy, communication, media and other industries.

It can achieve automatic stacking and unstacking of empty turnover boxes, while also having certain storage functions.

This product has a wide adaptability and can be used not only in conventional logistics center transportation systems, but also in airport baggage systems and mail processing center general contracting processing systems.

Use belt conveyor, alignment rollers, chutes and other components to align, separate, and intelligently queue parcel, which can integrate parcel from a stacked state into a single-piece queue state, and solve the stacking problem of goods and packages.

Through the use of round belt, bevel gear transmission or electric roller drive, etc., the servo motor controls the steering to achieve efficient sorting of packages of various specifications (cartons, waterproof bags, small packages) and heavy goods.&

It has the characteristics of dense arrangement, high reliability and high efficiency. It is suitable for matrix initial sorting, fine sorting before loading , or pick-and-roll part picking.

By retrofitting semi-trailer compartments, sorting equipment is placed inside the compartments and processing capacity is portable transferred to the required production site by means of automobile transport.

The device is convenient to move, flexible to deploy, secure and reliable.

Used for emergency delivery in remote mountainous areas, islands, and places with extremely high timeliness requirements, to solve the "last mile" problem of delivery safely, efficiently, and cost-effectively, and to achieve automation, unman

Maximum air speed: 16 meters/second; Load capacity 5kg

A weighing and scanning equipment that integrates weighing and code reading, using visual acquisition technology and electronic weighing technology to obtain barcode information, weight and volume information, quickly and accurately input it into the l

Widely used in the receiving and processing processes of express delivery and e-commerce industries.

Mainly used in comprehensive business outlets, it can meet the needs of users to self deliver domestic letters, domestic parcels, express delivery and other emails, as well as achieve online payment, subscription to newspapers, shopping on Youle websit

Integrated/Separate

Can significantly reduce delivery workload and improve technical delivery efficiency; Vehicle control through multi-directional intelligent decision-making is at a leading level in the industry. It has been put into operation in Deqing, Zhejiang, Xiant

Maximum speed of 15 kilometers per hour; Parts can be taken from both sides of the vehicle body

Applicable to multi category logistics processing center, single/double/three/four layer loop cross belt sorters have been formed, suitable for parcel sorting of large and small pieces with different specifications.

With the functions of double-end supply, “two-to-one”, flats induction, non-pole speed regulation, multi-language recognition, multi-face scanning, online video complement code, online automatic deviation correction, remote hierarchical management, and contactless power supply.